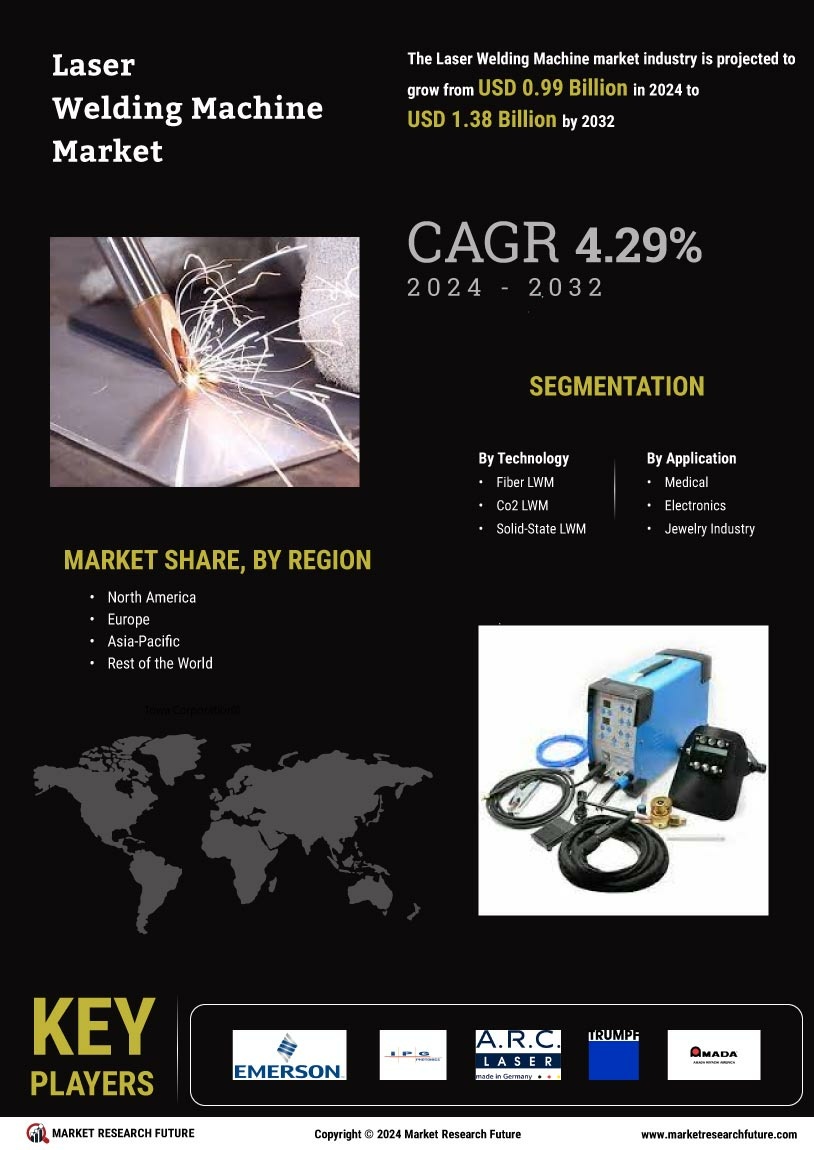

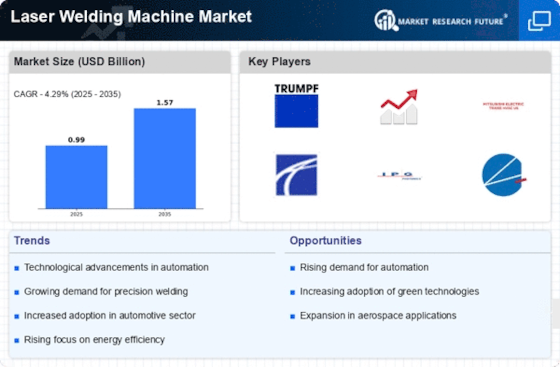

Rising Demand in Automotive Sector

The automotive sector is experiencing a notable increase in demand for laser welding machines industry, driven by the need for precision tools and efficiency in manufacturing processes. As vehicles become more complex, the Laser Welding Machine Market is adapting to meet these requirements. In 2025, it is estimated that the automotive industry will account for approximately 30% of the total share for laser welding machines market. This growth is attributed to the rising production of electric vehicles, which require advanced welding techniques to ensure structural integrity and performance. Furthermore, the shift towards lightweight materials in automotive design necessitates the use of laser welding, as it provides superior bonding capabilities without compromising material strength. Consequently, the automotive sector's expansion is likely to propel the Laser Welding Machine Market forward.

Increased Adoption in Aerospace Manufacturing

The aerospace manufacturing sector is increasingly adopting laser welding machines market, including automatic fiber laser welding machines, due to their ability to deliver high-quality welds with minimal thermal distortion. The Laser Welding Machine Market is witnessing a surge in demand as aerospace manufacturers seek to enhance production efficiency and reduce costs. In 2025, the aerospace industry is projected to represent around 20% of the market share for laser welding machines. This trend is driven by the need for lightweight and durable components, which are essential for modern aircraft. Laser welding technology allows for the joining of dissimilar materials, a critical requirement in aerospace applications. As the industry continues to innovate and expand, the reliance on advanced welding technologies is expected to grow, further solidifying the position of the Laser Welding Machine Market.

Growing Emphasis on Automation and Industry 4.0

The integration of automation and Industry 4.0 principles is transforming manufacturing processes across various sectors, including the Laser Welding Machine Market. As companies strive for increased efficiency and reduced operational costs, the demand for automated laser welding solutions is on the rise. In 2025, it is anticipated that automated systems will account for a significant portion of the market, driven by advancements in robotics and artificial intelligence. This shift towards automation not only enhances productivity but also improves the consistency and quality of welds. Furthermore, the ability to collect and analyze data in real-time allows manufacturers to optimize their processes, leading to better resource management. Consequently, the emphasis on automation is likely to propel the Laser Welding Machine Market into a new era of manufacturing excellence.

Expansion of Electronics and Electrical Industries

The electronics and electrical industries are increasingly relying on laser welding machines industry for the assembly of components, which is contributing to the growth of the Laser Welding Machine Market. As electronic devices become more compact and complex, the need for precise and reliable welding solutions is paramount. In 2025, it is estimated that the electronics sector will represent approximately 15% of the market share for laser welding machines. This growth is fueled by the rising demand for consumer electronics, including smartphones and wearable devices, which require intricate welding processes. Laser welding technology offers advantages such as reduced heat input and improved joint quality, making it ideal for delicate electronic components. As the electronics industry continues to evolve, the reliance on advanced welding technologies is expected to increase, further driving the Laser Welding Machine Market.

Emerging Applications in Medical Device Manufacturing

The medical device manufacturing sector is emerging as a significant driver for the Laser Welding Machine Market, as the demand for high-precision and reliable welding solutions grows. In 2025, it is projected that the medical device industry will account for around 10% of the share for laser welding machines market. This trend is largely attributed to the increasing complexity of medical devices, which require stringent quality standards and precise manufacturing techniques. Laser welding provides the necessary accuracy and control, making it suitable for joining materials used in medical applications, such as implants and surgical instruments. As the healthcare sector continues to innovate and expand, the reliance on advanced welding technologies is likely to increase, further enhancing the position of the Laser Welding Machine Market.